Question

In: Mechanical Engineering

Describe the main functions of drive trains or power transmission systems used in a milling machine....

Describe the main functions of drive trains or power transmission systems used in a milling machine. Include references if you can so I research further into it :)

Solutions

Expert Solution

A milling machine is a power driven machine that cuts by means of a multitooth rotating cutter. The mill is constructed in such a manner that the fixed workpiece is fed into the rotating cutter.

Working of a milling machine is based on the fact that milling cutter is fed against workpiece. This is achieved by developing relative motion with precise control between workpiece and rotating milling cutter. Feed motion is generally given to the workpiece through its holding device. Cutting mechanism of the workpiece in milling operations is same as that in turning operation on lathe. This cutting takes place due to plastic deformation of metal by the cutting tool. Milling machine can also hold more than one cutter at a time. The holding device is supported by mechanism that can offer a selective portion of the workpiece to milling cutter for its processing. Indexing is one of the examples of this type of processing.

PRINCIPAL PARTS OF A MILLING MACHINE

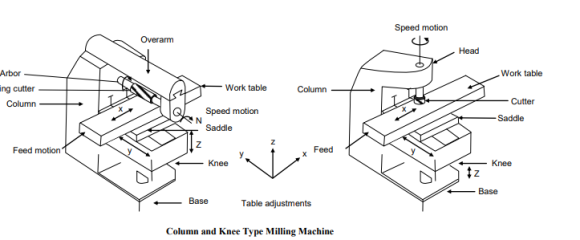

Generally columns and knee type milling machine is considered as typical milling machine. Principal parts of a typical milling machine are described as below.

Base

It provides rest for all parts of milling machine including column. It is made of grey iron by casting.

Column

It is a type of rigid vertical long box. It houses driving mechanism of spindle, table knee is also fixed to the guide ways of column.

Knee

Knee can be adjusted at a height on the column. It houses the feed mechanism of the table and other controls. Saddle

Saddle is placed at the top of the knee. Saddle provides guide ways for the movement of the table.

Table

Table rests on the saddle. It consists of „T? shaped slots for clamping the workpiece. Movements of the table (feed motions) are given in very controlled manner be lead screw.

Overhanging Arm

Overhanging arm is mounted on the column and serves a bearing support for the arbor. This arm is adjustable so that the bearing support may be provided near to the milling cutter. There can be more than one bearing supports to the arbor.

Arbor

It holds rotating milling cutters rigidly and mounted on the spindle. Sometimes arbor is supported at maximum distance from support of overhanging arm like a cantilever, it is called stub arbor. Locking provisions are provided in the arbor assembly to ensure its reliability.

Spindle

Spindle is projected from the column face and provided with a tapered hole to accommodate the arbor. Performance of a milling machine depends on the accuracy, strength and rigidity of the spindle. Spindle also transfer the motive power to arbor through belt or gear from column.

Mill Construction;

Mill Construction;

The vertical milling machine is made up of five major groups: base and column, knee, saddle, table, and head, (see figure). The base and column are one piece that forms the major structural component of the milling machine. They are cast integrally, ad provide the mill with its stability and rigidity. The front of the column has a machined face which provides the ways for the vertical movement of the knee. The knee supports the saddle and table. It contains the controls for raising and lowering the saddle. Sitting atop the knee is the saddle which supports the table. The saddle slides in dovetailed grooves into and away from the machine, providing the mill with its Y-axis movement. On top of the saddle sits the table. Being moved side-to-side, left-right, over the saddle furnishes the mill with its X-axis movement. The workpiece is secured to the table through the use of various types of holding devices.

The head is the most complex assembly in the major parts groups. This contains the following components:

1. The drive motor and on/off switch.

2. Drive belt, gear train, and range lever selector.

3. Quill, spindle, and draw bar.

4. Quill feed, lock, and digital depth read out (Z-axis).

The spindle is located within and moved up or down by the quill. This is the Z-axis movement for plunge operations on the vertical mill. The quill is moved by the quill feed lever, and can be locked in place with the quill lock. Depth of plunge moves are measured with the electronic digital read out located on the front of the mill head.

Related Solutions

Borg Power Trains produces drive-train components for all-wheel drive automobiles. For simplicity, assume the company produces...

Borg Power Trains produces drive-train components for all-wheel automobiles. For the year ended June 30, 2015...

Electric Power Systems What is transposition , why the transmission lines are transposed? please explain it...

Describe in details the association of urinary and genital systems and their functions

Describe the main regions and features of the Large Intestine. What are its main functions? What...

Describe major structures and functions of the male and female reproduction systems

Describe the main characteristics of caste systems, class systems, and status hierarchy systems. What role does...

Explain the concept of net filtration pressure. Describe the two main forces that drive the direction...

Describe how the capabilities of humans versus machines drive the allocation of functions in human-centered design....

Describe the general structures and functions of the integumentary and skeletal systems and how they work...

- Answer the following questions 1) How does ASC 606 — Revenue From Contracts With Customers(new standard...

- Project 7-6: Sales Tax Calculator Create a program that uses a separate module to calculate sales...

- On June 30, Sharper Corporation’s stockholders' equity section of its balance sheet appears as follows before...

- In this journal you are asked to take the role of a mayor or congressional representative...

- Answer correctly the below 25 multiple questions on Software Development Security. Please I will appreciate the...

- 1. The activation energy of a certain reaction is 41.5kJ/mol . At 20 ?C , the...

- Give TWO pieces of evidence that you've successfully made methyl salicylate. Remember when you cite TLC...

samet mamat answered 3 years ago

samet mamat answered 3 years ago