Question

In: Mechanical Engineering

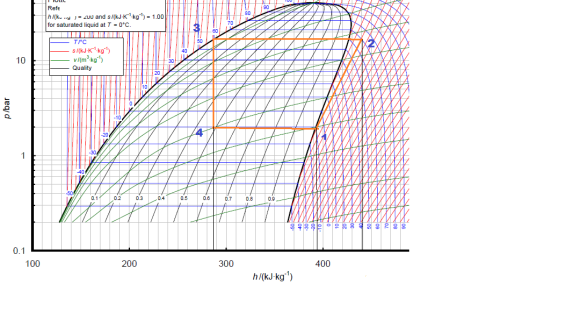

Statement: Selection of compressor and refrigerant for HVAC system that is operating on Vapor Compression Refrigeration...

Statement:

Selection of compressor and refrigerant for HVAC system that is

operating on Vapor Compression Refrigeration System. The heat load

is 120,000 BTU/hr and temperature is to be maintained at space is

50C.

Step 1:

Select ambient and environmental conditions

Step 2:

Select refrigerant, preliminary calculations, use of property

charts, suction discharge pressure of compressor to achieve

required cooling, compressor capacity etc.

Step 3:

Select compressor (Stage, rpm, displacement, size etc)

need detailed solution

Solutions

Expert Solution

1 room temperature 50c

condenser coil temperature = 60c

outside temperature = -10c

ambient pressure 1bar

2 refrigerant - R134a

heat load = 120,000btu/hr or 35.16kJ

condenser pressure P2 = 16.18bar(discharge of compressor )

t2 = 70

specific energy lost bby condenser = h2-h3 = 438-288 = 150kJ/kg

mass flow rate of refrigerant m = 35.16/150 = 0.23kg/sec

no subcooling

evaporator temperature -10deg c assuming isentropic expansion

specific energy gained by the evaporator = h1-h4 = 394-288 = 106kJ/kg

specific workdone by compressor = 150-106 = 44kJ/kg

suction pressure of compressor = 2.006bar

3

single stage compressor

specific volume at stage1 v1 = 0.09959m^3/kg

volume flow at suction Qc = m*v1 = 0.023m^3/sec

p1 = 2.006 bar

p2= 16.18 bar

compression ratio = 16.18/2.006 = 8.065

stroke of cylinder = 0.2m

bore of cylinder = 0.1m

swept volume of cylinder V = .2*(.1^2*0.785)m^3 = 1.57*10^-3m^3

hence the size of compressor = 1.57Lt

speed of rotation = N rpm

volume flowrate = V*N/(2*60)m^3/sec

which is equal to v1 = 0.023 = 1.57*10^-3*N/(2*60)

hence the speed of compressor N = 1757.96RPM

Related Solutions

An air conditioner using refrigerant-134a as the working fluid and operating on the ideal vapor-compression refrigeration...

There is a vapor compression type refrigeration cycle using the refrigerant HFC 134 a. In the...

A vapor-compression refrigeration system for a household refrigerator has a refrigerating capacity of 1650 Btu/h. Refrigerant...

design a vapor compression refrigeration system that will maintain the refrigerated space at -15c while operating...

An ideal vapor compression refrigeration cycle using r134a as the refrigerant is being used to cool...

An ice-making machine operates on the ideal-vapor compression cycle using refrigerant-134a. The refrigerant enters the compressor...

A vapor-compression refrigeration cycle operates at steady state with Refrigerant 134a as the working fluid. Saturated...

A single stage simple vapr compression refrigeration cycle using R12 refrigerant is operating at a condenser...

Refrigerant 134a enters an insulated compressor operating at steady state as saturated vapor at -26oC with...

Refrigerant 134a enters an insulated compressor operating at steady state as saturated vapor at -20oC with...

- Project 7-6: Sales Tax Calculator Create a program that uses a separate module to calculate sales...

- On June 30, Sharper Corporation’s stockholders' equity section of its balance sheet appears as follows before...

- In this journal you are asked to take the role of a mayor or congressional representative...

- Answer correctly the below 25 multiple questions on Software Development Security. Please I will appreciate the...

- 1. The activation energy of a certain reaction is 41.5kJ/mol . At 20 ?C , the...

- Give TWO pieces of evidence that you've successfully made methyl salicylate. Remember when you cite TLC...

- Describe briefly the evolution of Craniata and Vertebrata.

samet mamat answered 1 year ago

samet mamat answered 1 year ago