Question

In: Physics

A 38-mm thick HMA surface course is to be designed to carry 15,000,000 ESALs during the...

A 38-mm thick HMA surface course is to be designed to carry 15,000,000 ESALs during the life of the pavement. A 9.5-mm nominal size aggregate is required. The aggregates shown in Table 4-14 are available for use. The control limits and restricted zone boundary are shown in Table 4-10. Based on environmental information, a PG 64-22 is used as the binder. Design a HMA mix according to the Superpave method.

Solutions

Expert Solution

ASPHALT BINDER

Asphalt is produced in a variety of types and grades ranging from hard-brittle solids to near waterthin liquids. The semi-solid form known as asphalt binder is the basic material used in asphalt pavements. Liquid asphalt is produced when asphalt binder is blended or “cut back” with petroleum distillates or emulsified with water and an emulsifying agent. At ambient air temperatures, asphalt binder is a black, sticky, highly viscous material. It is a strong and durable binder with excellent adhesive and waterproofing characteristics. Applying heat, which facilitates mixing with mineral aggregates to produce asphalt pavement, can readily liquefy asphalt binders. The largest use of asphalt binder is for asphalt pavement. After compacting and cooling to air temperature, asphalt pavement is a very strong paving material with the ability to sustain heavy traffic loads while remaining flexible enough to withstand ambient environmental conditions and stresses. Over 96 percent of the hard-surfaced roads in the United States are paved using asphalt pavement.

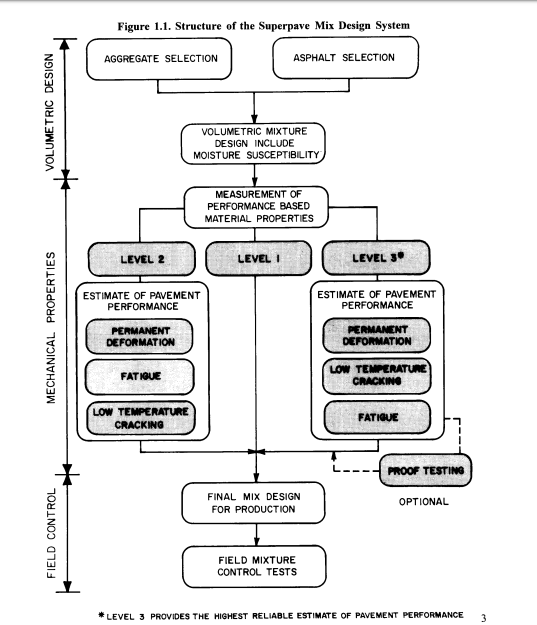

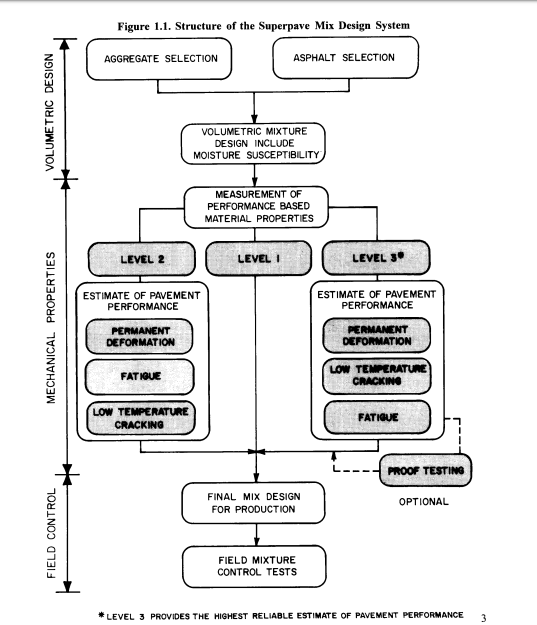

Superpave Mix Design

One of the principal results from the Strategic Highway Research Program (SHRP) was the Superpave mix design method. The Superpave mix design method was designed to replace the Hveem and Marshall methods. The volumetric analysis common to the Hveem and Marshall methods provides the basis for the Superpave mix design method. The Superpave system ties asphalt binder and aggregate selection into the mix design process, and considers traffic and climate as well. The compaction devices from the Hveem and Marshall procedures have been replaced by a gyratory compactor and the compaction effort in mix design is tied to expected traffic.

Under the Strategic Highway Research Program (SHRP), an initiative was undertaken to improve materials selection and mixture design by developing:

- A new mix design method that accounts for traffic loading and environmental conditions.

- A new method of asphalt binder evaluation

- New methods of mixture

analysis.

SUPERPAVE PROCEDURE:

- Aggregate selection.

- Asphalt binder selection.

- Sample preparation (including compaction).

- Performance Tests.

- Density and voids calculations.

- Optimum asphalt binder content selection.

- Moisture susceptibility evaluation

Gradation Specifications

Superpave mix design specifies aggregate gradation control points, through which aggregate gradations must pass.These control points are very general and are a starting point for a job mix formula.

Aggregate Blending

It is rare to obtain a desired aggregate gradation from a single aggregate stockpile. Therefore, Superpave mix designs usually draw upon several different aggregate stockpiles and blend them together in a ratio that will produce an acceptable final blended gradation. It is quite common to find a Superpave mix design that uses 3 or 4 different aggregate stockpiles

Gyratory compactor

Superpave gyratory compactor sample (left) vs. Hveem/Marshall compactor sample (right).

Typically, samples are compacted to Ndesign to establish the optimum asphalt binder content and then additional samples are compacted to Nmax as a check. Previously, samples were compacted to Nmax and then Ninitial and Ndesign were back calculated. Table 6 lists the specified number of gyrations for Ninitial, Ndesign and Nmax while Table 7 shows the required densities as a percentage of theoretical maximum density (TMD) for Ninitial, Ndesign and Nmax.

Number of Gyrations for Ninitial, Ndesign and Nmax

| 20-yr Traffic Loading (in millions of ESALs) |

Number of Gyrations | ||

| Ninitial | Ndesign | Nmax | |

| Less than 0.3 | 6 | 50 | 75 |

| 0.3 to | 7 | 75 | 115 |

| 3 to | 8 (7) | 100 (75) | 160 (115) |

| 10 to | 8 | 100 | 160 |

| ≥ 30 | 9 | 125 | 205 |

| * When the estimated 20-year design traffic loading is between 3 and initial = 7, Ndesign = 75 and Nmax = 115. |

Required Densities for Ninitial, Ndesign and Nmax

| 20-yr Traffic Loading (in millions of ESALs) |

Required Density (as a percentage of TMD) | ||

| Ninitial | Ndesign | Nmax | |

| Less than 0.3 | ≤ 91.5 | 96.0 | ≤ 98.0 |

| 0.3 to | ≤ 90.5 | ||

| 3 to | ≤ 89.0 | ||

| 10 to | |||

| ≥ 30 |

Density and Voids Analysis

All mix design methods use density and voids to determine basic HMA physical characteristics. Two different measures of densities are typically taken:

- Bulk specific gravity (Gmb).

- Theoretical maximum specific gravity (TMD, Gmm).

These densities are then used to calculate the volumetric parameters of the HMA. Measured void expressions are usually:

- Air voids (Va), sometimes expressed as voids in the total mix (VTM)

- Voids in the mineral aggregate (VMA)

- Voids filled with asphalt (VFA)

Related Solutions

The inner and outer surface temperatures of a glass window 5 mm thick are 15 and...

The inner surface of a 5 cm diameter, 3 mm thick, and 7 cm high styrofoam...

Assuming a planar surface, calculate how long it will take to dissolve 1 mm thick layer...

A low-carbon steel plate is 270 mm wide and 25 mm thick. It is reduced in...

A cast iron water pipe of 500 mm inside diameter and 20 mm thick, is supported...

A Copper plate that is 588mm wide and 48 mm thick is to be reduced in...

500 mm thick square footing is to be placed at a depth of 0.5 m in...

500 mm thick square footing is to be placed at a depth of 0.5 m in...

500 mm thick square footing is to be placed at a depth of 0.5 m in...

At 130°C, a bronze hoop 20 mm thick whose inside diameter is 600 mm just fits...

- Project 7-6: Sales Tax Calculator Create a program that uses a separate module to calculate sales...

- On June 30, Sharper Corporation’s stockholders' equity section of its balance sheet appears as follows before...

- In this journal you are asked to take the role of a mayor or congressional representative...

- Answer correctly the below 25 multiple questions on Software Development Security. Please I will appreciate the...

- 1. The activation energy of a certain reaction is 41.5kJ/mol . At 20 ?C , the...

- Give TWO pieces of evidence that you've successfully made methyl salicylate. Remember when you cite TLC...

- Describe briefly the evolution of Craniata and Vertebrata.

genius_generous answered 3 years ago

genius_generous answered 3 years ago