Question

In: Statistics and Probability

Western Technical Services is a small engineering firm in Colorado that provides a variety of technical...

Western Technical Services is a small engineering firm in Colorado that provides a variety of technical and drafting services. Western Technical Services employs three engineers, five drafters, and three secretaries. Western has developed a leading reputation in the design of low-capacity and medium-capacity heat exchangers for electrical equipment. A large backlog of jobs has accumulated, and the firm has decided it must complete the back orders. The firm wants to maximize the number of jobs finished each day to eliminate its backlog. The average time required to design a medium-capacity heat exchangers is 4 hours of engineering time, 3 hours of time by a drafter, and 3 hours of secretarial work. Designing a low-capacity heat exchanger requires an average of 1.5 hours of work from an engineer, 4 hours of work from a drafter, and 1.5 hours of secretarial effort.

Formulate a linear programming problem that Western could use to determine how best to employ its resources in order to maximize the total number of heat exchangers that can be completed each day subject to the firm’s labor constraints. I.e. the objective of the firm in this problem is to maximized total output (Q). (Hint: Q = 1M + 1L where M = the number of medium capacity heat exchangers completed and L = the number of low capacity heat exchangers completed each day) Assume that the engineers and drafters each work 10-hour days, and the secretaries work 8 hours per day.

Solve the linear programming problem and interpret the solution. How many heat exchangers will be completed each day? Your assignment is to maximize output (i.e. maximize the number total number of heat exchangers produced subject to the constraints provided.) Hint: The total number, i.e. quantity, of heat exchangers is Total output Q = 1M + 1L. You are trying to determine the maximum number the firm can produce given its production constraints.

Solutions

Expert Solution

Let M be the number of medium capacity heat exchangers completed each day and L be the number of low capacity heat exchangers completed per day

these are the decision variables

The total number of heat exhangers produced per day is M+L

The firm wants to maximize the total number of exchangers produced per day

The objective function is to maximize M+L

Following are the constraints

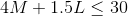

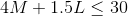

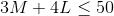

Engineering hours

- Each of the 3 engineers can work 10 hours per day, for a total

30 hours of Engineering time per day. The engineering time required

to produce M and L quantities is

and this has to be less than or equal to 30

and this has to be less than or equal to 30

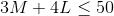

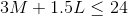

Drafter hours

- Each of the 5 drafters can work 10 hours per day, for a total

50 hours of drafter time per day. The drafter time required to

produce M and L quantities is

and this has to be less than or equal to 50

and this has to be less than or equal to 50

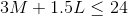

Secretarial hours

- Each of the 3 secretaries can work 8 hours per day, for a total

24 hours of secretarial time per day. The secretarial time required

to produce M and L quantities is

and this has to be less than or equal to 24

and this has to be less than or equal to 24

The linear programming model is

maximize

s.t.

We prepare the following excel

get these values

set up the solver using data--->solver

get the following solution

To maximize the total number of exhanges produced per day, given the production constraints, the firm needs to produce 2.8 medium capacity and 10.4 low capacity heat exhangers. The fractional values will indicate the partially completed heat exhangers during the day.

Related Solutions

Part A MelSwin is an accounting consultancy firm that provides its services to small, medium and...

Part A MelSwin is an accounting consultancy firm that provides its services to small, medium and...

Part A MelSwin is an accounting consultancy firm that provides its services to small, medium and...

Part A MelSwin is an accounting consultancy firm that provides its services to small, medium and...

Eclipse Engineering provides services of structural engineering. They just opened a new branch in Portland, OR....

ERF Enterprises provides comprehensive AV services to institutions in the State of Colorado. Their customers fall...

Texas Building Services provides cleaning services for a variety of clients. The company has two producing...

1. The Westfall Relocation Company, located in Denver, Colorado provides services to laid-off employees of major...

Your company provides a variety of delivery services. Management wants to know the volume of a...

Evans Park Evans Park is a small amusement park that provides a variety of rides for...

- In long paragraphs answer the questions below: Discuss the key components (where, when, what) and causes...

- Sinkal Co. was formed on January 1, 2018 as a wholly owned foreign subsidiary of a...

- Larry’s best friend, Garfield, owns a lasagna factory. Garfield’s financial skills are not very strong, so...

- Redox/Oxidation lab with Metals and Halogens So basically we were testing different reactions and observing changes....

- CORAL LANGUAGE ONLY Write a function DrivingCost with parameters drivenMiles, milesPerGallon, and dollarsPerGallon, that returns the...

- do you believe, as bonilla-silva does, that convert forms of racism are widespread? why or why...

- A bicycle wheel has a diameter of 63.9 cm and a mass of 1.86 kg. Assume...

and this has to be less than or equal to 30

and this has to be less than or equal to 30

and this has to be less than or equal to 50

and this has to be less than or equal to 50

and this has to be less than or equal to 24

and this has to be less than or equal to 24

orchestra answered 3 years ago

orchestra answered 3 years ago