Question

In: Accounting

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in...

Way Cool produces two different models of air conditioners. The

company produces the mechanical systems in its components

department. The mechanical systems are combined with the housing

assembly in its finishing department. The activities, costs, and

drivers associated with these two manufacturing processes and the

production support process follow.

| Process | Activity | Overhead Cost | Driver | Quantity | ||||

| Components | Changeover | $ | 596,050 | Number of batches | 910 | |||

| Machining | 376,184 | Machine hours | 7,970 | |||||

| Setups | 72,000 | Number of setups | 40 | |||||

| $ | 1,044,234 | |||||||

| Finishing | Welding | $ | 322,380 | Welding hours | 5,400 | |||

| Inspecting | 256,725 | Number of inspections | 815 | |||||

| Rework | 71,400 | Rework orders | 280 | |||||

| $ | 650,505 | |||||||

| Support | Purchasing | $ | 181,125 | Purchase orders | 525 | |||

| Providing space | 30,900 | Number of units | 4,200 | |||||

| Providing utilities | 46,380 | Number of units | 4,200 | |||||

| $ | 258,405 | |||||||

Additional production information concerning its two product lines

follows.

| Model 145 | Model 212 | |||||

| Units produced | 1,400 | 2,800 | ||||

| Welding hours | 1,400 | 4,000 | ||||

| Batches | 455 | 455 | ||||

| Number of inspections | 495 | 320 | ||||

| Machine hours | 2,650 | 5,320 | ||||

| Setups | 20 | 20 | ||||

| Rework orders | 150 | 130 | ||||

| Purchase orders | 350 | 175 | ||||

Required:

1. Using ABC, compute the overhead cost per unit

for each product line.

2. Determine the total cost per unit for each

product line if the direct labor and direct materials costs per

unit are $190 for Model 145 and $116 for Model 212.

3. If the market price for Model 145 is $821.61

and the market price for Model 212 is $498.56, determine the profit

or loss per unit for each model.

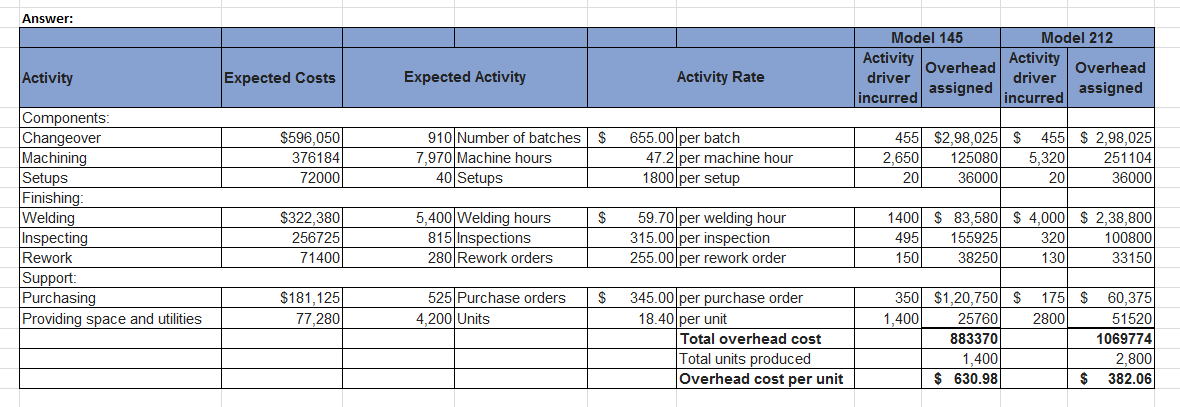

Using ABC, compute the overhead cost per unit for each product line. (Round your final answers to 2 decimal places.)

Required 1:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

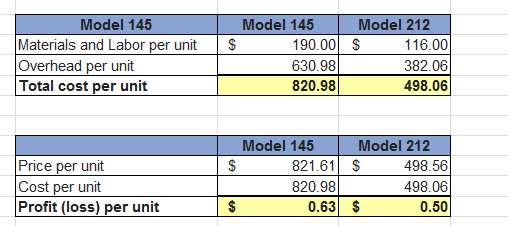

Required 2:

Determine the total cost per unit for each product line if the direct labor and direct materials costs per unit are $190 for Model 145 and $116 for Model 212. (Round your final answers to 2 decimal places.)

|

Required 3:

If the market price for Model 145 is $821.61 and the market price for Model 212 is $498.56, determine the profit or loss per unit for each model. (Round your final answers to 2 decimal places.)

|

Solutions

Related Solutions

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in...

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in...

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in...

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in...

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in...

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in...

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in...

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in...

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in...

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in...

- CORAL LANGUAGE ONLY Write a function DrivingCost with parameters drivenMiles, milesPerGallon, and dollarsPerGallon, that returns the...

- do you believe, as bonilla-silva does, that convert forms of racism are widespread? why or why...

- A bicycle wheel has a diameter of 63.9 cm and a mass of 1.86 kg. Assume...

- Cane Company manufactures two products called Alpha and Beta that sell for $150 and $110, respectively....

- What’s the cost of each component of capital and which need to be adjusted? What do...

- Answer the following questions 1) How does ASC 606 — Revenue From Contracts With Customers(new standard...

- Project 7-6: Sales Tax Calculator Create a program that uses a separate module to calculate sales...

ekkarill92 answered 3 months ago

ekkarill92 answered 3 months ago