Question

In: Civil Engineering

1. Explain the basic treatment categories for hazardous waste. 2. Determine the compacted waste to soil...

1. Explain the basic treatment categories for hazardous waste.

2. Determine the compacted waste to soil ratio (by volume) for an assumed compacted waste density of 500 kg/m3. The design disposal rate is 60 tons per day. The cell height and width will be 3.0 m and 5.0 m respectively. Take the slope of working faces as 3 horizontal to 1 vertical. The prescribed daily soil cover thickness is to be 200 mm.

3. It is mandatory that a civil engineer research a potential site and then design a construction and operation plan based on local geological characteristics before an operator can safely build a landfill. You have to design a new landfill with a 25 year lifespan. Determine the compacted landfill waste volume, the cover soil volume required and the landfill footprint area. The soil burrow pit is estimated to be 5 m deep. The solid waste generated per capita average 3.0 kg/day. The initial rate of deposition is 200 tons/day. The population growth rate is 2% per annum. The estimated compacted density of the waste at the site is 700 kg/m3. The minimum buffer zone to the landfill is to be 500 m. Assume a volumetric ratio of cover material to compacted waste of 1:4. Assume an 8 hectare allowance for landfill facilities.

4. Anaerobic digestion and aerobic digestion are processes that breakdowns biodegradable material. Discuss the application for this processes with regards to solid waste management

5. Describe the mechanical biological treatment system and state five possible advantages of this system.

6. The “waste hierarchy” ranks waste management options according to what is best for the environment. Describe the waste hierarchy.

7. Determine the classification of a landfill that yields evaporation records of 2 200 mm per year and rainfall of 600 mm per year. The site receives only general waste from a rural community and the estimated current disposal rate is 0,80 Tons per day. The site life is expected to be 7 years.

8. The final cover of a landfill functions as a way to keep water out of the contaminate and to control the runoff from entering the system. Draw an annotated drawing of a class G: L: B - landfill.

9. State and discuss the role of MRFs in an Integrated Solid Waste Management System

Solutions

Expert Solution

1.

The disposal process for hazardous waste and nonhazardous waste can vary considerably, so it is imperative to know what is considered hazardous waste and what is not. The EPA defines three types of hazardous waste: listed, characteristic, and mixed radiological waste. Each of these categories has subcategories that can become very precise, but the basics are as follows.

Listed Wastes:

Listed wastes are those that come from manufacturing processes and

identifiable industries or can be created from commercial product

chemical wastes. There are four types of listed waste: F, K, P, and

U waste.

F-List Waste

Wastes on the F-list come from non-specific sources. They are

generated from manufacturing and industrial processes, but these

processes can occur in many different sectors of industry. The EPA

defines seven groups of F-list wastes and they are grouped by the

manner in which they are created.

K-List Waste

In contrast to F-list wastes, K-list wastes do have specific

sources. They, too, come from manufacturing and industrial

processes, but they originate from identifiable industries such as

wood preservation, petroleum refining, and explosives

manufacturing. There are 13 of these categories; detailed

descriptions can be found in the Code of Federal Regulations, Title

40 section 261.32.

P- and U-List Waste

P- and U-listed wastes indicate pure, unused chemicals intended for

disposal and they share three criteria: they contain one of the

chemicals on the P or U list, said chemical is unused in the waste,

and the chemical is in the form of a commercial chemical

product.

P-list waste is acute waste and its empty containers are treated as hazardous waste. U-list waste is also toxic, but the empty containers are not considered hazardous.

Characteristic Wastes:

Characteristic wastes are defined by their exhibition of at least

one of the following properties: ignitability, corrosivity,

reactivity, and toxicity.

Ignitable: Waste that can be set on fire. Wastes with this quality include compressed gases, solid waste prone to spontaneous combustion, and liquids with flashpoints below 60 °C.

Corrosive: Waste that is able to eat away at another substance through chemical reactions. Hazardous wastes with this quality include liquid waste with a pH of 2 and below or of 12.5 and above. Corrosivity may also be based on the substance’s ability to corrode steel.

Reactive: Waste that is unstable under typical conditions. These hazardous wastes may have chemical reactions with water or give detonate with heat. Explosives and lithium-sulfur batteries are considered reactive hazardous wastes.

Toxic: Waste that is harmful or fatal when ingested or absorbed by living things. Examples of toxic hazardous waste include arsenic and chloroform. A full list of toxic waste and the regulatory levels at which they are considered hazardous can be found in 40 CFR 262.24.

Mixed Radiological Wastes:

The final category of hazardous waste is mixed radiological waste,

which means that the waste has both a hazardous and a radioactive

component. Because it contains two types of regulated wastes, the

disposal of mixed radiological wastes must comply with the RCRA and

the Atomic Energy Act. It is the Department of Energy or the

Nuclear Regulatory Commission that regulates the radiological part

of that hazardous waste.

Determining whether or not your company is producing hazardous waste, what category it falls into, and how to properly dispose of that waste can be a difficult and tedious processes.

Ans.4.-

Anaerobic digestion is commonly used to treat sludges in the first areas of a wastewater treatment plant. This process is popular because it is able to stabilize the water with little biomass production. Anaerobic treatment occurs in many different stages.

Aerobic digestion is present everywhere that organic matter decomposes in the open air with an abundant air circulation.

Anaerobic digestion is around us everywhere the spores are in the air just as are the organisms of aerobic decay. Even in a well turned compost heap, some parts are likely to lack enough air fro aerobic processes and some anaerobic digestion will be taking place.

A good indication of anaerobic digestion is the unpleasant smell, in comparison to the “earthy” but not unpleasant odors of aerobic systems (for example, as in “compost heaps.

The following is a comparison of aerobic and anaerobic digestion.

In an anaerobic system there is an absence of gaseous oxygen.

In an anaerobic digester, gaseous oxygen is prevented from entering the system through physical containment in sealed tanks. Anaerobes access oxygen from sources other than the surrounding air. The oxygen source for these microorganisms can be the organic material itself or alternatively may be supplied by inorganic oxides from within the input material.

When the oxygen source in an anaerobic system is derived from the organic material itself, then the ‘intermediate' end products are primarily alcohols, aldehydes, and organic acids plus carbon dioxide.

In an aerobic system, such as composting, the microorganisms access free, gaseous oxygen directly from the surrounding atmosphere. The end products of an aerobic process are primarily carbon dioxide and water which are the stable, oxidized forms of carbon and hydrogen.

Ans.5:-

A mechanical biological treatment (MBT) system is a type of waste processing facility that combines a sorting facility with a form of biological treatment such as composting or anaerobic digestion. MBT plants are designed to process mixed household waste as well as commercial and industrial wastes.

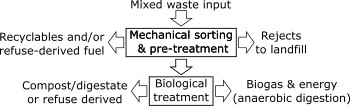

Process flow chart

The terms mechanical biological treatment or mechanical biological pre-treatment relate to a group of solid waste treatment systems. These systems enable the recovery of materials contained within the mixed wasteand facilitate the stabilisation of the biodegradable component of the material.[1][2]

The sorting component of the plants typically resemble a materials recovery facility. This component is either configured to recover the individual elements of the waste or produce a refuse-derived fuel that can be used for the generation of power.

The components of the mixed waste stream that can be recovered include:

- Ferrous metal

- Non-ferrous metal

- Plastic

- Glass. The five advantages of this system are:

- These systems enable the recovery of materials contained within the mixed waste and facilitate the stabilisation of the biodegradable component of the material

- This either removes recyclable elements from mixed waste stream or process them.

- The sorting component of the plants typically resemble a materials recovery facility.

- By processing the biodegradable waste either by anaerobic digestion or by composting MBT technologies help to reduce the contribution of greenhouse gases to global warming.

Reduction of the waste volume to be

deposited to at least a half (density > 1.3 t/m³), thus the

lifetime of the landfill is at least twice as long as usual

Utilisation of the leachate in the process.

Ans.6:-

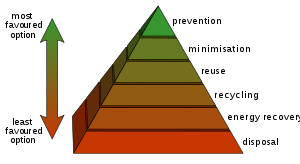

The waste hierarchy.

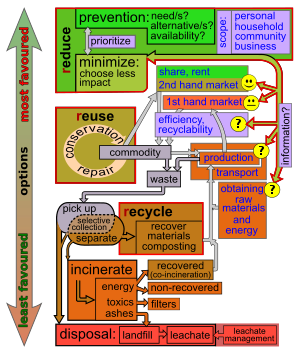

Enhanced version of waste hierarchy.

The three chasing arrows of the international recycling logo. It is sometimes accompanied by the text "reduce, reuse and recycle".

Waste hierarchy is a tool used in the evaluation of processes that protect the environment alongside resource and energy consumption from most favourable to least favourable actions.[1] The hierarchy establishes preferred program priorities based on sustainability.[1] To be sustainable, waste management cannot be solved only with technical end-of-pipe solutions and an integrated approach is necessary.[2]

The waste management hierarchy indicates an order of preference for action to reduce and manage waste, and is usually presented diagrammatically in the form of a pyramid.[3]The hierarchy captures the progression of a material or product through successive stages of waste management, and represents the latter part of the life-cycle for each product.[3]

The aim of the waste hierarchy is to extract the maximum practical benefits from products and to generate the minimum amount of waste. The proper application of the waste hierarchy can have several benefits. It can help prevent emissions of greenhouse gases, reduces pollutants, save energy, conserves resources, create jobs and stimulate the development of green technologies.

Ans.9:-

A materials recovery facility, materials reclamation facility, materials recycling facility or Multi re-use facility (MRF, pronounced "murf") is a specialized plant that receives, separates and prepares recyclable materials for marketing to end-user manufacturers. Generally, there are two different types: clean and dirty materials recovery facilities.

A clean MRF accepts recyclable materials that have already been separated at the source from municipal solid waste generated by either residential or commercial sources. There are a variety of clean MRFs. The most common are single stream where all recyclable material is mixed, or dual stream MRFs, where source-separated recyclables are delivered in a mixed container stream (typically glass, ferrous metal, aluminum and other non-ferrous metals, PET [No.1] and HDPE [No.2] plastics) and a mixed paper stream including corrugated cardboard boxes, newspapers, magazines, office paper and junk mail. Material is sorted to specifications, then baled, shredded, crushed, compacted, or otherwise prepared for shipment to market.

Mixed-waste processing facility (MWPF)/ Dirty MRF :

A mixed-waste processing system, sometimes referred to as a dirty MRF, accepts a mixed solid waste stream and then proceeds to separate out designated recyclable materials through a combination of manual and mechanical sorting. The sorted recyclable materials may undergo further processing required to meet technical specifications established by end-markets while the balance of the mixed waste stream is sent to a disposal facility such as a landfill. Today, MWPFs are attracting renewed interest as a way to address low participation rates for source-separated recycling collection systems and prepare fuel products and/or feedstocks for conversion technologies. MWPFs can give communities the opportunity to recycle at much higher rates than has been demonstrated by curbside or other waste collection systems. Advances in technology make today’s MWPF different and, in many respects better, than older versions. [10]

The percentage of residuals (unrecoverable recyclable or non-program materials) from a properly operated clean MRF supported by an effective public outreach and education program should not exceed 10% by weight of the total delivered stream and in many cases it can be significantly below 5%.[citation needed] A dirty MRF recovers between 5% and 45% of the incoming material as recyclables,[citation needed] then the remainder is landfilled or otherwise disposed. A dirty MRF can be capable of higher recovery rates than a clean MRF, since it ensures that 100% of the waste stream is subjected to the sorting process, and can target a greater number of materials for recovery than can usually be accommodated by sorting at the source. However, the dirty MRF process results in greater contamination of recyclables, especially of paper. Furthermore, a facility that accepts mixed solid waste is usually more challenging and more expensive to site. Operational costs can be higher because it is more labor-intensive.

Related Solutions

Determine, using the procedures outlined by RCRA, if each of the following is a hazardous waste....

list and explain briefly five disposal technologies for hazardous waste

QUESTION 1 Distinguish between solid waste and hazardous waste in terms of definition. Discuss the management...

Write a 2 to 3 page literature review on how is hazardous waste controlled in developing...

1. What are the three basic manufacturing cost categories? 2. What are the main difference between...

2 There are two (2) laboratory tests can be conducted to determine the coefficient of soil...

Treatment 1 Treatment 2 Treatment 3 0

ASSIGNMENT WEEK 1 (Metal Casting) 1. Name the two basic categories of casting processes. (CO1,C2) 2....

Please explain the travel distribution model and what are its 3 basic categories?

1. Identify and give examples of each three basic manufacturing cost categories. 2.During April, $52,000 in...

- 1. The activation energy of a certain reaction is 41.5kJ/mol . At 20 ?C , the...

- Give TWO pieces of evidence that you've successfully made methyl salicylate. Remember when you cite TLC...

- Describe briefly the evolution of Craniata and Vertebrata.

- How many grams are in a 0.10 mol sample of ethyl alcohol?

- For this assignment you will write a program with multiple functions that will generate and save...

- How many grays is this?Part A A dose of 4.7 Sv of γ rays in a...

- how to operate a business?

Ally Wells answered 2 years ago

Ally Wells answered 2 years ago