Question

In: Accounting

Advanced Technologies (AT) produces two compression machines that are popular with manufacturers of plastics: no. 165...

Advanced Technologies (AT) produces two compression machines that are popular with manufacturers of plastics: no. 165 and no. 172. Machine no. 165 has an average selling price of $29,800, whereas no. 172 typically sells for approximately $27,300. The company is very concerned about quality and has provided the following information: No. 165 No. 172 Number of machines produced and sold 140 190 Warranty costs: Average repair cost per unit $ 890 $ 330 Percentage of units needing repair 70 % 10 % Reliability engineering at $130 per hour 1,590 hours 1,990 hours Rework at AT's manufacturing plant: Average rework cost per unit $ 1,880 $ 1,590 Percentage of units needing rework 40 % 25 % Manufacturing inspection at $60 per hour 290 hours 490 hours Transportation costs to customer sites to fix problems $ 29,300 $ 14,600 Quality training for employees $ 34,600 $ 49,600

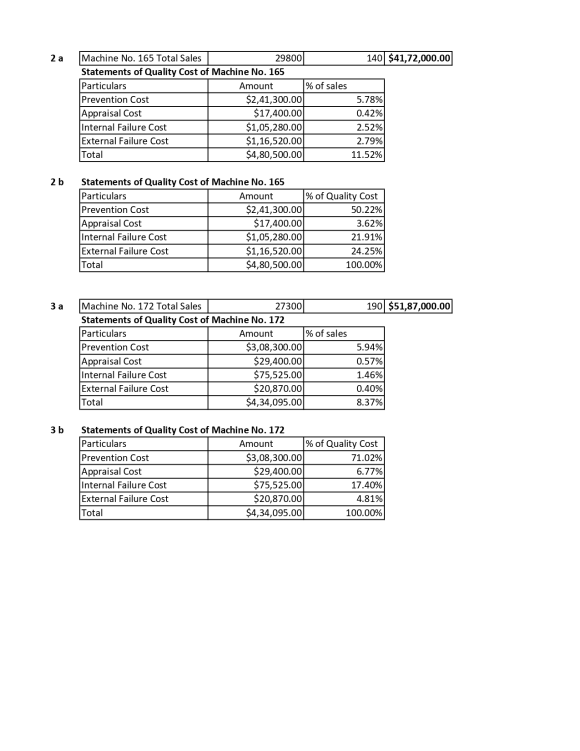

Required: 2-a. Using the classifications in requirement (1), compute AT's quality costs for machine no. 165 in dollars and as a percentage of sales revenues. (Round "Percentage of Sales" to 2 decimal places.)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2-b. Using the classifications in requirement (1), compute AT's calculate prevention, appraisal, internal failure, and external failure costs as a percentage of total quality costs. (Round "Percentage of Total Quality Costs" to 2 decimal places. Total may not be equal to 100% due to rounding.)

|

|||||||||||||||||||||||||||

3-a. Using the classifications in requirement (1), compute AT's quality costs for machine no. 172 in dollars and as a percentage of sales revenues. (Round "Percentage of Sales" to 2 decimal places.)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3-b. Using the classifications in requirement (1), compute AT's calculate prevention, appraisal, internal failure, and external failure costs as a percentage of total quality costs. (Round "Percentage of Total Quality Costs" to 2 decimal places. Total may not be equal to 100% due to rounding.)

|

|||||||||||||||||||||||||||

Solutions

Expert Solution

Solution.

Quality Cost refers to the costs that are incurred to prevent, detect and remove defects from products. Quality costs are categorized into four main types. Theses are:

- Prevention costs -The costs incurred to avoid or minimize the number of defects at first place are known as prevention costs.

- Appraisal costs (also known as inspection costs) are those cost that are incurred to identify defective products before they are shipped to customers.

- Internal failure costs are costs that are caused by products or services not conforming to requirements or customer/user needs and are found before delivery of products and services to external customers. They would have otherwise led to the customer not being satisfied

- External failure costs- If defective products have been shipped to customers, external failure costs arise.

Related Solutions

Advanced Technologies (AT) produces two compression machines that are popular with manufacturers of plastics: no. 165...

Write a two page Essay on the Advanced Risk Machines (ARM) company and about it's main...

The manufacturers of Good-O use two different types of machines to fill their 25 kg packs...

The manufacturers of Good-O use two different types of machines to fill their 25 kg packs...

Rose Sdn. Bhd. (RSB) produces two products, which are Standard and Advanced. The followings are the...

JOBCO produces two products on two machines. A unit of product 1 requires 2 hours on...

KPhone produces quality smart phones. Its factory produces two popular models: the KPhone Pro and the...

Two popular fiber ring technologies are FDDI (runs at 100 Mbps) and SONET (2.4 Gbps). Both...

Good Scent, Inc., produces two colognes: Rose and Violet. Of the two, Rose is more popular....

1. JOBCO produces two products on two machines. A unit of product 1 requires 2 hours...

- What’s the cost of each component of capital and which need to be adjusted? What do...

- Answer the following questions 1) How does ASC 606 — Revenue From Contracts With Customers(new standard...

- Project 7-6: Sales Tax Calculator Create a program that uses a separate module to calculate sales...

- On June 30, Sharper Corporation’s stockholders' equity section of its balance sheet appears as follows before...

- In this journal you are asked to take the role of a mayor or congressional representative...

- Answer correctly the below 25 multiple questions on Software Development Security. Please I will appreciate the...

- 1. The activation energy of a certain reaction is 41.5kJ/mol . At 20 ?C , the...

ekkarill92 answered 3 years ago

ekkarill92 answered 3 years ago