Question

In: Mechanical Engineering

In wire drawing, is there a difference and if so how much is the force required...

In wire drawing, is there a difference and if so how much is the force required to draw a wire from cross sectional area of A0 down to A1 in one operation as compared to drawing it through two dies in tandem. Assume that there is friction but no redundant work

Solutions

Expert Solution

Ans. In wire drawing a circular cross section billet is reduced in diameter and increased in length by pulling through a conical die of semi angle.

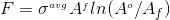

Expression for drawing force under frictionless condition is given by

Where Sigma average is the average true stress of material.

Ao= original cross section area

Af= final cross section area

Because more work has to be done to overcome friction , the force increases with increasing Friction.

As reduction increases the drawing force increases.

There is a limit to force due to tensile stress reaches yield stress of metal so our billet will simply yield and eventually breaks.

Maximum reduction in the cross section area per pass is limited to 63%.

Drawing through two dies in tandem will not matter ideally for drawing force if we assume frictionless condition. But in real application force required depends on strength of the billet material , friction between billet and chamber of dies surface and process variables such as temperature and speed of drawing.

Related Solutions

Q1: What is the difference between bar drawing and deep drawing? What is the difference between a...

a) How much force is the air exerting on the front cover of a book that...

need a detailed answer so much. Thanks a lot! The question is: "Describe the difference between...

Drawing on your knowledge of the balance of payments so far, explain how the three elements...

1. In "magnetic force on a current carrying wire" experiment, using the data for force(y-axis, in...

What is the magnitude of the net force on the first wire in (figure 1)?

What is the difference between a two-wire and three-wire motor control circuit?

Three forces are applied to an object, as indicated in the drawing. Force F with arrow1...

How much protein is required? What does the book say about the required protein for a...

55,000J of work is done to move a rock 25m. How much force was applied?

- Project 7-6: Sales Tax Calculator Create a program that uses a separate module to calculate sales...

- On June 30, Sharper Corporation’s stockholders' equity section of its balance sheet appears as follows before...

- In this journal you are asked to take the role of a mayor or congressional representative...

- Answer correctly the below 25 multiple questions on Software Development Security. Please I will appreciate the...

- 1. The activation energy of a certain reaction is 41.5kJ/mol . At 20 ?C , the...

- Give TWO pieces of evidence that you've successfully made methyl salicylate. Remember when you cite TLC...

- Describe briefly the evolution of Craniata and Vertebrata.

samet mamat answered 1 year ago

samet mamat answered 1 year ago